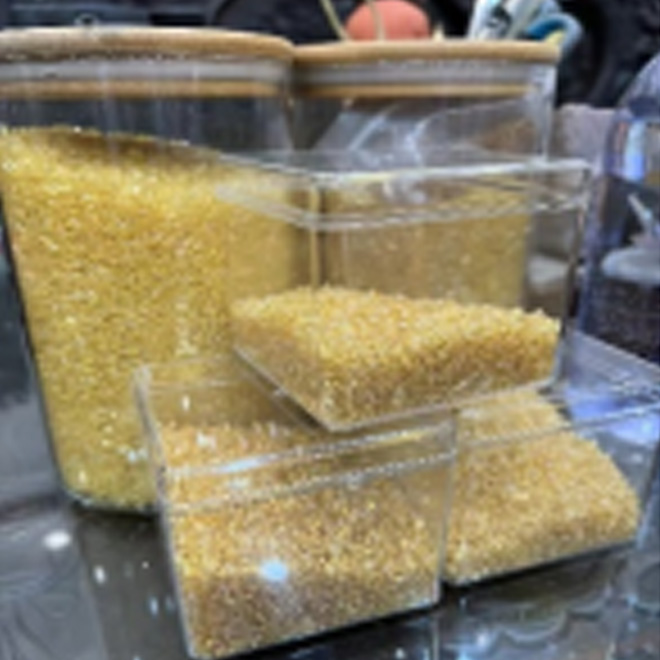

PEI

Polyetherimide (PEI) is an amber-colored transparent solid with inherent flame retardancy and low smoke emission without the addition of any additives. It has an oxygen index of 47% and a UL94-V-0 burning rating. The density of PEI ranges from 1.28 to 1.42 g/cm³. PEI exhibits excellent thermal stab

Send InquiryProduct Details

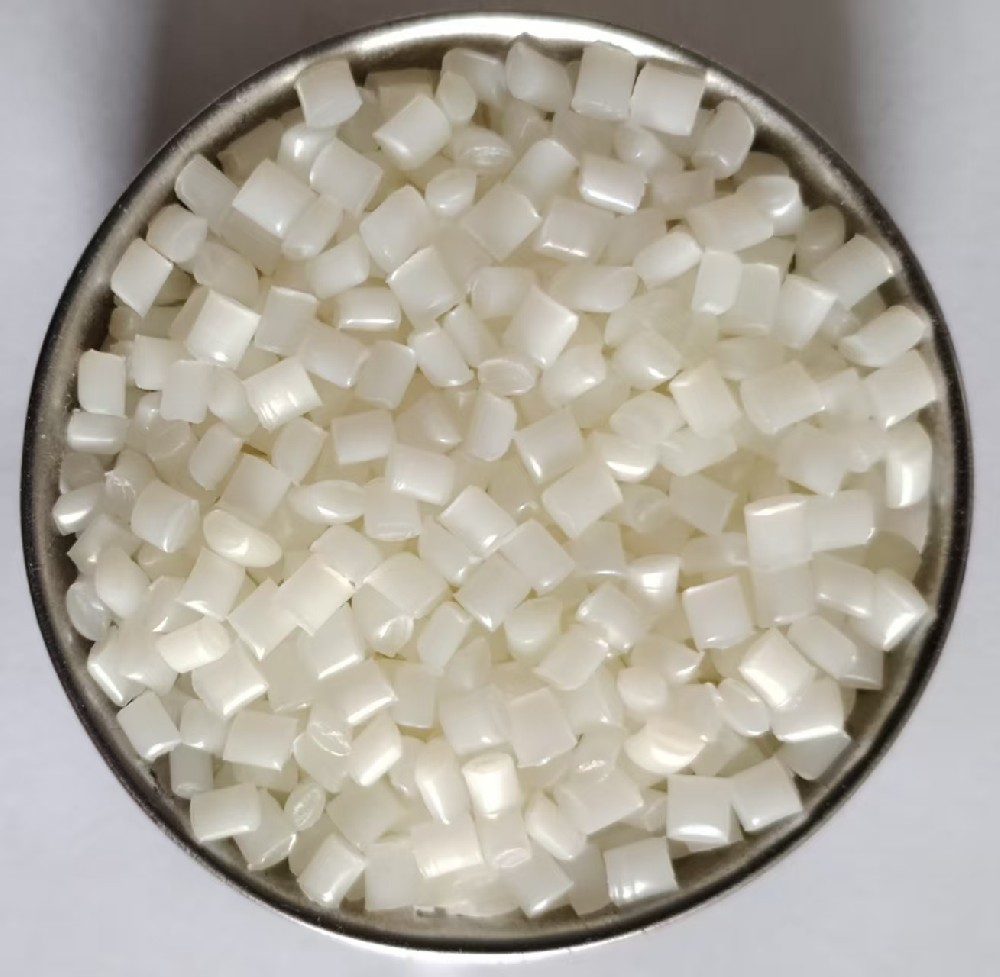

Polyetherimide (PEI) is an amber-colored transparent solid with inherent flame retardancy and low smoke emission without the addition of any additives. It has an oxygen index of 47% and a UL94-V-0 burning rating. The density of PEI ranges from 1.28 to 1.42 g/cm³. PEI exhibits excellent thermal stability, even in its non-reinforced form, maintaining good toughness and strength. Therefore, it can be used to manufacture high-temperature resistant devices due to its superior heat resistance properties. PEI possesses outstanding mechanical properties, electrical insulation, radiation resistance, high/low temperature resistance, and wear resistance, as well as microwave transparency. Additionally, PEI has good flame retardancy, chemical resistance, and electrical insulation characteristics. Its glass transition temperature is very high at 215°C. PEI also has a low shrinkage rate and excellent isotropic mechanical properties. Reinforcement can be achieved by adding glass fibers, carbon fibers, or other fillers; it can also be combined with other engineering plastics to form heat-resistant polymer alloys that can operate within a temperature range of -160°C to 180°C for extended periods.

Description:PEI

Product Model: VET 001

Typical Features: Excellent mechanical,electrical and dimensional properities up to high temperature,good chemical resisitance,flame retartant,

Properties

Describe | Typical features | Typical applications |

VET 002 (unreinforced) | Flame ratardant, Chemicalresisitance, goodprocessabilty, Hydrolytic stability, Low warpage, Low smoke and toxicity, Low corrosivity, | Water management, Automotive under the hood Energy management wireless-communication Personal and professional Hygiene Patient Testing |

VET 002G10 (10% glass fiber reinforced) | Flame ratardant, Chemicalresisitance, goodprocessabilty, Hydrolytic stability, Low warpage, Low smoke and toxicity, Low corrosivity, | Recreational/Specialty vehicles Consumer Goods Personal Accessory Pharmaceutical Packaging and Drug Dekivery Electrical ,Material Handing Eyewear |

VET 002G30 (30% glass fiber reinforced) | Flame ratardant, Chemicalresisitance, goodprocessabilty, Hydrolytic stability, Low warpage, Low smoke and toxicity, Low corrosivity, | Water management, Automotive under the hood Energy management wireless-communication Personal and professional Hygiene Patient Testing Large Fomt Addotove Manufacturing (LFAN) |

Applications:

Fiber optic head of Electrical Hairdressing comb of Consumer Goods The gear of Energy management